MACHINE SHOP SERVICES

Our People Have Decades of Experience Providing Machine Shop Services

Machining Capabilities

| Turning | CNC Lathes | To 40.5" × 118" (1030mm x 3000mm)

2 Axis/3 Axis/4 Axis |

|---|---|---|

| 3 Axis with Live Tooling/Milling | ||

| 4 Axis with Live Tooling/Milling | ||

| Y-Axis | ||

| CNC Vertical Boring Mill | To 78.75" × 67.75" (2000mm x 1550mm) | |

| 3 Axis with Live Tooling/Milling | ||

| Manual | To 31.5" × 118" (800mm x 3000mm) with DRO | |

| Milling | CNC - 4 Axis; | To 79" × 59" (2000mm x 1500mm) |

| CNC Horizontal Milling Center | 39.4" × 39.4" (1000mm x 1000mm) pallets | |

| 78.7"×49.2“×49.2" (2000mm x 1250mm x 1250mm)

working envelope |

✚Turning

- CNC Lathes

- To 40.5" × 118" (1030mm x 3000mm) 2 Axis/3 Axis/4 Axis

- 3 Axis with Live Tooling/Milling

- 4 Axis with Live Tooling/Milling

- Y-Axis

- CNC Vertical Boring Mill

- To 78.75" × 67.75" (2000mm x 1550mm)

- 3 Axis with Live Tooling/Milling

- Manual

- To 31.5" × 118" (800mm x 3000mm) with DRO

✚ Milling

- CNC - 4 Axis

- To 79" × 59" (2000mm x 1500mm)

- CNC Horizontal Milling Center

- 39.4" × 39.4" (1000mm x 1000mm) pallets

- 78.7"×49.2“×49.2" (2000mm x 1250mm x 1250mm) working envelope

Request Gear Application Answers + Contact Us

At Delta Dynamics, We Deliver Precision

-

Gear Machining For Gears

-

General Machining

-

CNC Gear Grinding

-

Industrial Gearbox Services

-

Gear Cutting

CNC GEAR GRINDING

A machining process used to finish grind gear teeth to a high precision and surface finish. Gear grinding is typically done for high speed, high load, or high tolerance applications.

Gear Grinding Of Tolerances

Of Up To

AGMA Q15 For 1 To 32 Inches In Diameter

Gear grinding teeth offers the ability to fine-tune gear micro geometry to produce stronger, quieter meshing, and higher quality gears. our machines come equipped with on-board gear inspection to ensure we meet all of our customers' specifications.

GEAR HOBBING

Is an efficient method to cut external teeth for spur gears, helical gears, worm gears, splines, sprockets, timing chain, and custom relatively good accuracy (up to AGMA Q9).

Hobbed Parts From 0.5 To 96 Inches In Diameter

And 80 To 1 Diametral Pitch.

GEAR SHAPING

A machining process used to cut internal or external teeth in spur gears, splines, and custom tooth profiles. Internal and external helical gears can be shaped but require special cutters and additional tooling.

Shaped Parts From 0.5 to 60 Inches

In Diameter

And 64 to 2 Diametral Pitch.

Shaping is a versatile method of cutting teeth with parts that have tight physical constraints such as shoulders and oru horizontal shapers have the ability to cut internal or external teeth at ends of long parts. Shaping can produce parts with accuracy up to AGMA Q10 and a better surface finish than conventional hobbing.

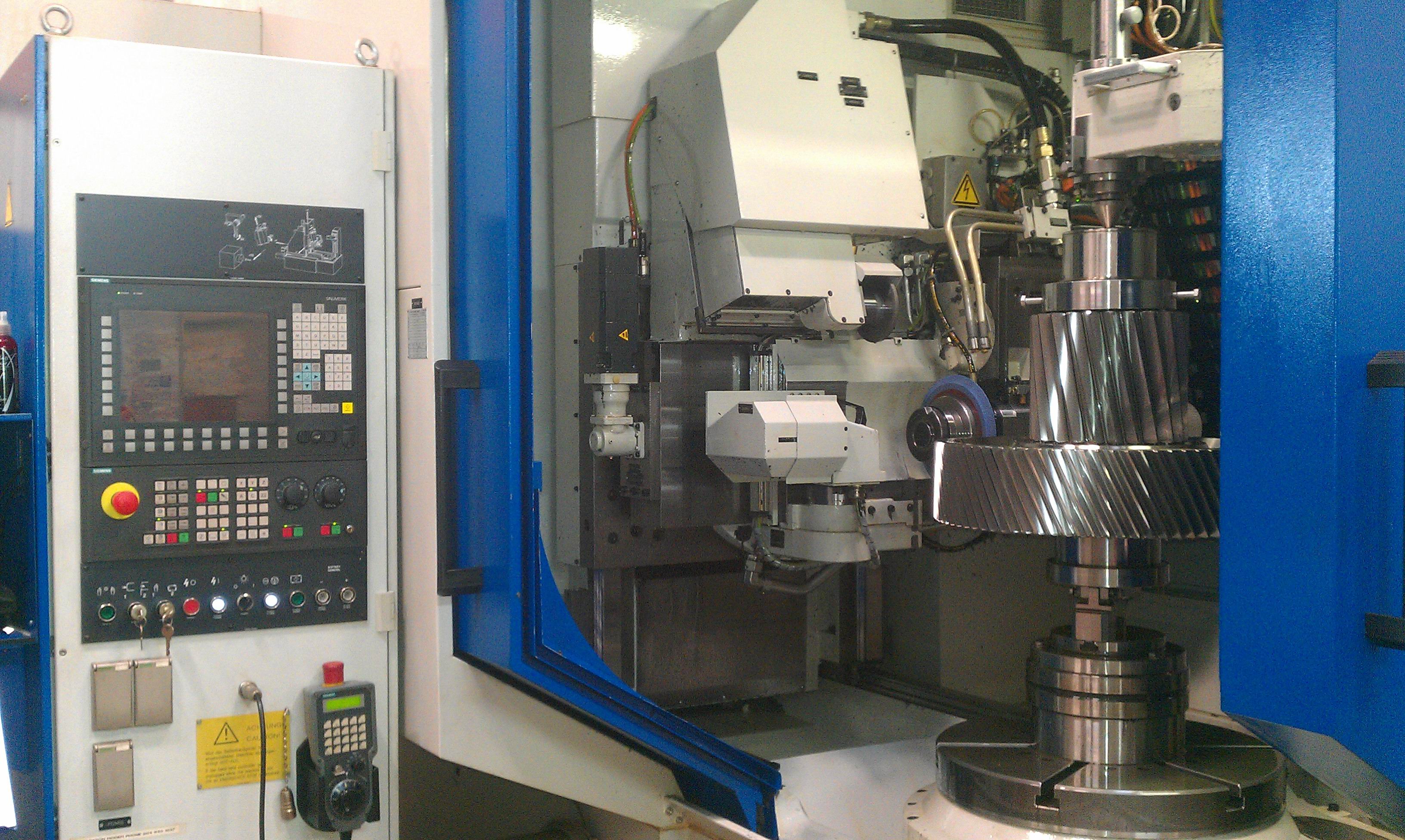

INDUSTRIAL GEAR BOX SERVICES - GEAR REDUCER FAILURE

Gear reducer failure is a serious problem which is why gearbox rebuild and repair is such an important part of what Delta Dynamics does. This reducer, pictured on the left, was designed and built by another machine shop to handle the increased horsepower that an Aluminum Smelter wanted to put through it. The gears lasted two weeks.

The experts at Delta Dynamics were able to analyze the situation and perform industrial gearbox services. The large-width gears were theoretically capable of handling very high horsepower. However, the large torque in the system wound up the pinion shaft so that the actual gear contact length was much smaller than designed. With our help, gear reducer failure problems will be minimized and eliminated so that your machinery may work as it is intended to.

INDUSTRIAL GEAR BOX SERVICES - REDUCER REBUILT

As shown in the image on the left, Delta Dynamics built a set of gears to replace the failed helical set above. The double helical design eliminates all thrust loads on the bearings which really emphasizes the strength and power of gearbox rebuild and repair, as the bearings were one of the constricting factors with the increased horsepower. The double helical design with axial float on the pinion allowed full-face contact regardless of the torsional windage. The gear reducer has been running for well over 6 years.

General Machining